Should I Get a Wrought Iron or Aluminum Fence?

If you’ve ever walked through a historic neighborhood, you’ve probably seen some beautiful wrought iron fences. Perhaps you are considering building your own. But do you really need wrought iron to get that look? Aluminum is a modern alternative with many benefits. We’ll walk you through a comparison of wrought iron and aluminum to help you figure out whether wrought iron or aluminum is for you.

Wrought Iron Fence

Wrought iron is iron that has been worked (wrought is an archaic form of the past participle for work). That means that is has been hammered or rolled while hot. Today, real wrought iron is no longer commercially produced. Mild steel, which is very similar to wrought iron, is often used in its place, and may even be referred to as wrought iron by some. In many cases, wrought iron is used to designate the style, including all forms of decorative metal fence.

Aluminum Fence

Aluminum is a popular stand-in for wrought iron. It has many of the same benefits as wrought iron and avoids some of its problems. Aluminum fences are not new, but they have become much more popular over the last decade. Some homeowner associations require aluminum for all new fences to preserve a uniform style for the neighborhood.

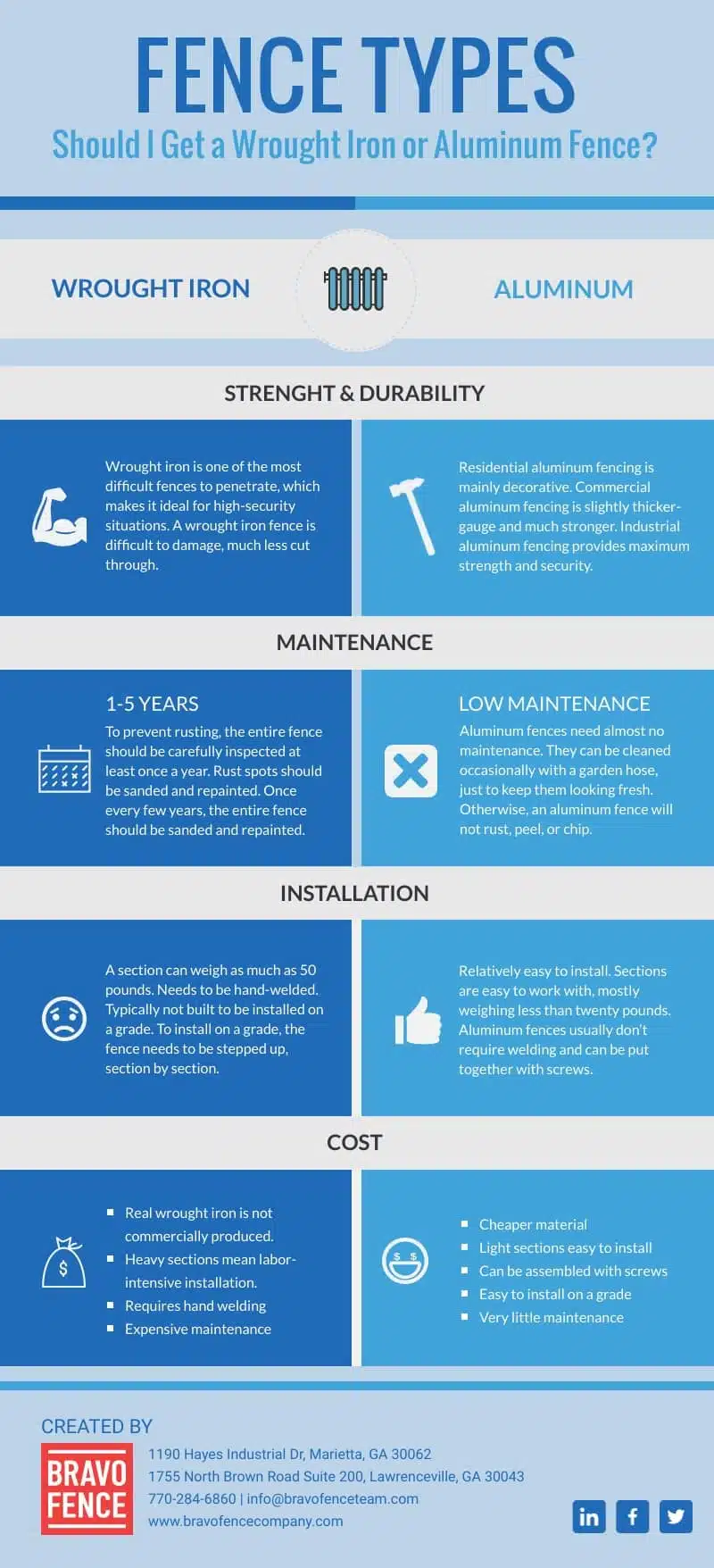

Strength and Durability

Wrought iron is one of the most difficult fences to penetrate, which makes it ideal for high-security situations. A wrought iron fence is difficult to damage, much less cut through.

Aluminum, on the other hand, is less sturdy than wrought iron. Residential aluminum fencing can be dented or bent if enough force is applied. In most situations, aluminum is an effective barrier, and residential aluminum fencing is mainly decorative. If you need more strength, you can turn to commercial aluminum fencing, which is slightly thicker-gauge and much stronger. For high-traffic, high-security areas, industrial aluminum fencing provides maximum strength and security.

Maintenance

A wrought iron fence requires significant maintenance to keep it from falling into disrepair. The biggest problem with wrought iron is that it rusts. To prevent rusting, the entire fence should be carefully inspected for corrosion at least once a year. Any rust spots should be sanded and repainted to avoid further damage. Once every few years, the entire fence should be sanded and repainted. This can make wrought iron fences expensive to maintain.

Aluminum fences need almost no maintenance. They can be cleaned occasionally with a garden hose, just to keep them looking fresh. Otherwise, an aluminum fence will not rust, peel, or chip.

Installation

Installing a wrought iron fence is a labor-intensive job. A section of wrought iron fence can weigh as much as 50 pounds. And the wrought iron needs to be hand-welded together. Wrought iron is typically not built to be installed on a grade. If a wrought iron fence will be installed on a grade, the fence needs to be stepped up, section by section.

Aluminum fence is relatively easy to install. Its sections are easy to work with, mostly weighing less than twenty pounds. Aluminum fences usually don’t require welding and can be put together with screws.

Cost

Wrought iron fencing is some of the most expensive fencing you can get. Authentic wrought iron has to be produced by a skilled blacksmith and can run in the hundreds or even thousands of dollars per section. Mild steel is commercially available, so it can be cheaper, but it is still an expensive option. The heavy weight of wrought iron or mild steel fencing makes it labor-intensive to install. The added labor means added cost. The hand welding necessary for wrought iron also increases costs significantly. Finally, wrought iron needs regular maintenance and even repainting. To repaint a wrought iron fence, the existing paint needs to be sanded off, which can be a large job. Caring for a wrought iron fence can be quite expensive. Due to the nature of wrought iron and its tendency to rust, many wrought iron fences have warranties as short as ten years.

Aluminum fencing is much less expensive than wrought iron. It is easier to produce, and therefore the fence sections are cheaper. At less than twenty pounds a section, installation is much simpler. Aluminum fencing can also be easily installed on a grade, saving labor on uneven ground. It is also relatively easy to install since it usually does not require welding. Because the installation is easier and faster, installation costs are much lower than wrought iron. There are also hardly any maintenance costs. Warranties are often for the lifetime of the fence.

The Final Decision

Deciding between wrought iron and aluminum comes down to a choice between an expensive, labor-intensive luxury item and a durable, cost-effective, authentic-looking alternative.

Wrought Iron Pros:

- Classic Look

- Extremely Durable with Proper Care

- Sturdy material provides high security.

Wrought Iron Cons:

- Expensive

- Hard to Work With

- Requires Hand Welding

- Regular, Expensive Maintenance

Aluminum Pros:

- Mimics Classic Look of Wrought Iron

- Light and Easy to Work With

- Installed With Screws

- Much Cheaper Than Wrought Iron

- Very Low Maintenance

- Available in Residential, Commercial, and Industrial Grades to Match Your Strength and Durability Needs

Aluminum Cons:

- Not 100% Authentic

- Residential Grade Fencing Not as Sturdy as Wrought Iron

At this point, it should be pretty clear that aluminum is almost always a better option. Bravo Fence installs all types of aluminum fencing, from classic to modern styles and all grades. If you’re ready to find out more about aluminum fencing, contact Bravo Fence Company for more details and a free quote.