Metal Fences: The Ultimate Guide

Metal fences have a long history as an upscale alternative to historically more affordable wood fences. When most people think of metal fencing, they think of wrought iron. However, most metal fencing today is made of steel or aluminum, which is much easier to fabricate, much lighter than wrought iron, and much more cost-effective. Wrought iron is, by definition, handmade, so the costs can be prohibitive. Steel and aluminum fencing can be prefabricated, and they are light enough to be fashioned into panels. That makes them much more cost-effective to produce and to install. If you are ready to install a metal fence, you may be wondering which type of fence is ideal for you. This guide will outline the history and different kinds of metal fencing to help you decide what is best for your home or business.

Wrought Iron

The first ornamental metal fences were made of wrought iron. Wrought refers to metal that is beaten out or shaped by hammering, requiring extensive labor by a skilled blacksmith. In the Colonial period, only the wealthiest Americans could afford wrought iron because it had to be hand fabricated in England and shipped to the colonies. However, in the early nineteenth century, local factories began to produce cast iron fencing that retained the look of wrought iron but brought this kind of ornamental fencing within reach of many more Americans. However, the cast-iron fence pieces were still extremely heavy and complicated to install.

Modern Metal Fences

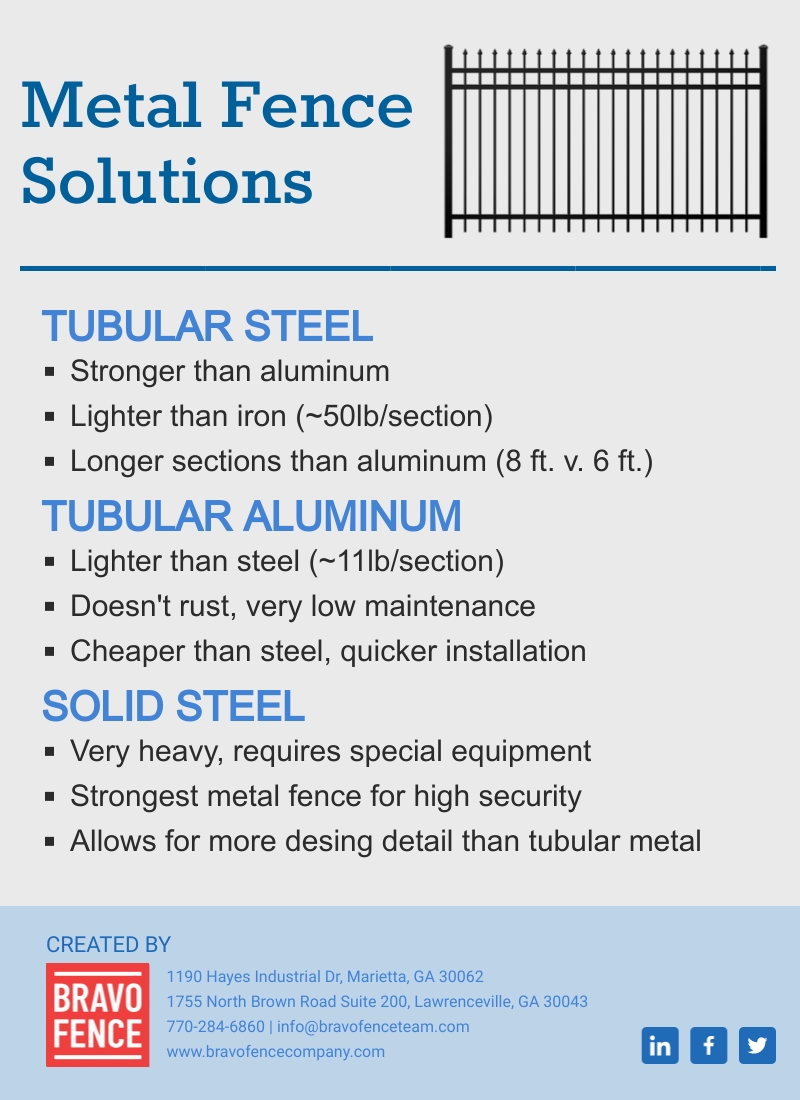

Today, most ornamental metal fencing is made of tubular steel or aluminum. The pieces can be machined in a factory and installed on site. Because the metals are lighter and the posts, rails, and pickets are hollow, tubular steel and aluminum can be sold as complete panels, which are much more efficient to install. The lower production and labor costs make ornamental steel and aluminum viable alternatives to other materials without driving costs through the roof.

Tubular steel and aluminum fences can also be shipped with the rails, posts, and pickets disassembled, making them much easier to transport. The components are then assembled onsite with fasteners. Some homeowners combine tubular steel or aluminum fencing with cast iron ornaments for a more traditional look since cast iron allows greater detail than machined steel or aluminum.

Tubular Steel

Tubular steel is made to mimic the look of traditional wrought iron. It is produced from metal sheets that are bent into posts, pickets, and rails. The pieces are coated with a rust-proof primer and then painted. Most homeowners paint their tubular steel fences shiny black to mirror the traditional look of wrought iron. However, it can be painted practically any color to match your personal design.

Tubular steel comes standard with 5/8-inch hollow pickets to match the style of wrought iron. Look for tubular steel fencing with hidden fasteners. The more hidden the fasteners are, the more solid the whole fence will look.

Tubular Steel Maintenance

Steel, like cast iron, is an alloy of iron and carbon with other elements, so it can still rust. But modern tubular steel metal fences are treated with coatings that prevent rust. If the coating is scratched, it can expose the metal to rust, but the repairs are simple. To repair a scratched or even slightly rusted area of steel fence, start by sanding down the area to remove any rust or loose paint. Sand all the way down to the bare metal. Next, paint over that area with a rust-inhibiting metal primer. Finally, cover the primer with paint to match the rest of the fence.

Installing Tubular Steel

An 8-foot long section of 4-foot tall tubular steel fence can weigh 50 pounds, making it challenging to install yourself. If you want the strength of steel, your best bet is to hire professionals like Bravo Fence Company. We have the right tools to install tubular steel fencing that looks like wrought iron at a fraction of the cost. To find out more and get a quote, contact Bravo Fence Company.

Tubular Aluminum

Tubular aluminum has many of the same features as tubular steel, but with several advantages. One significant advantage of tubular aluminum has to do with weight. While an 8-foot section of 4-foot tall steel fencing can weigh 50 pounds, a 6-foot section of aluminum weighs just 11 pounds. However, because aluminum is not as strong as steel, it’s not practical to build sections longer than 6 feet, compared to 8 feet for steel. So an aluminum fence needs more posts than a steel fence. Each post requires digging a pit and installing a cement footing. Over a long distance, the difference between 8-foot and 6-foot sections can mean quite a few more posts to install.

The second advantage of aluminum over steel is aluminum’s nearly nonexistent maintenance. Aluminum is not an iron alloy, and so it cannot rust. It is susceptible to some corrosion, but with a standard powder coating, aluminum requires almost no maintenance.

Limits of Tubular Steel and Aluminum

While tubular steel and aluminum are great materials for an average ornamental fence, they still have some limitations compared to wrought (or cast) iron. The most significant difference is the level of detail possible in ornamentations. Tubular steel and aluminum allow for a variety of finials and some level of ornamentation in the shapes of the fence. But intricate loops, scrolling, and braiding are difficult to achieve with hollow posts, rails, and pickets.

Solid Steel

One alternative that allows for more detailed ornamentation is solid steel. Solid steel is extremely heavy and requires special machinery to hoist into place. It is also significantly more expensive than hollow steel. But it allows for designs that mimic almost anything possible with traditional wrought iron.

Another limitation of tubular steel and aluminum is its strength as security fencing. Steel is stronger than aluminum, but because they are hollow, neither one is as strong as solid metal. For added strength, some homeowners and commercial properties select tubular steel with thicker walls. But nothing beats the strength of solid steel. For high-security applications, solid steel is still the best option.

Proper Installation

Whether you choose steel or aluminum, proper installation is critical. If you want the look of real wrought iron—and who doesn’t—you need to install your metal fence perfectly. Hiding fasteners, getting every edge perfectly straight and lined up, and racking or stepping for sloped surfaces all make a huge difference. So if you are ready to install the ornamental metal fence of your dreams, it’s time to contact Bravo Fence Company. We have the experience and expertise to install the best metal fences with the best results.